Recycled parts collision repair offers significant cost savings and environmental benefits by meticulously refurbishing used auto parts to meet OEM standards. Skilled technicians ensure structural integrity, dimensional accuracy, and material composition match new parts, restoring vehicles to pre-accident conditions while maintaining safety and performance. This sustainable solution reduces auto body shops' carbon footprint, minimizes waste, and provides affordable, high-quality repairs, making it an attractive eco-friendly choice for businesses and consumers alike.

In today’s world, where sustainability is paramount, recycled parts collision repair stands out as a game-changer. This article explores how using repurposed components meets Original Equipment Manufacturer (OEM) standards, ensuring both quality and efficiency. We delve into the environmental and economic benefits of this innovative approach to automotive restoration, showcasing its potential to revolutionize the industry while mitigating ecological impact. Understanding recycled parts is crucial in navigating the future of collision repair.

- Understanding Recycled Parts and Their Role in Collision Repair

- Ensuring Quality: How Recycled Parts Meet OEM Standards

- The Environmental and Economic Benefits of Using Recycled Parts for Collision Repair

Understanding Recycled Parts and Their Role in Collision Repair

Recycled parts have emerged as a significant player in the collision repair industry, offering both environmental and economic benefits for car collision repair and body shop services. These parts are not your typical, new-off-the-line components. Instead, they’re meticulously refurbished and remanufactured from used auto parts, giving them a new lease of life. This process involves careful disassembly, cleaning, inspection, and reconstruction to meet Original Equipment Manufacturer (OEM) standards for both functionality and quality.

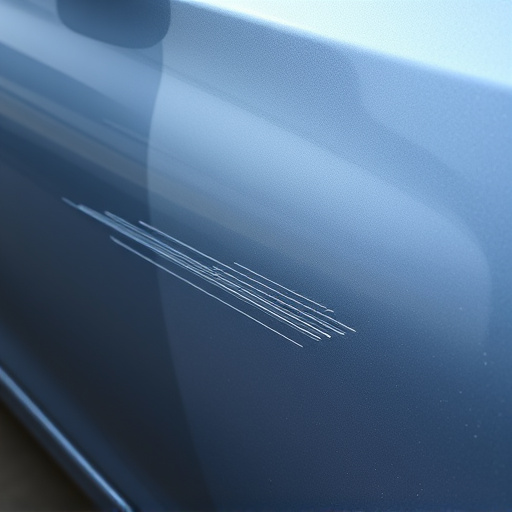

In the realm of car collision repair, recycled parts are a sustainable solution that can significantly reduce costs while maintaining vehicle aesthetics. From replacing fenders and hoods to intricate interior components, these reused parts ensure that vehicles not only return to their pre-accident condition but also contribute to a more eco-friendly approach to body shop services. This is particularly relevant in today’s world where environmental consciousness is on the rise.

Ensuring Quality: How Recycled Parts Meet OEM Standards

In the realm of recycled parts collision repair, ensuring quality is paramount to meeting Original Equipment Manufacturer (OEM) standards. This meticulous process involves rigorous inspection and testing protocols that mirror those used for new OEM parts. Every recycled component undergoes a comprehensive evaluation to verify its structural integrity, dimensional accuracy, and material composition, ensuring it performs identically to its original counterpart.

At the collision center, skilled technicians play a pivotal role in this quality control. They scrutinize each part, employing advanced tools and expertise to detect even subtle defects or discrepancies. This meticulous approach guarantees that recycled parts not only restore the car’s exterior to its pre-accident condition but also maintain the vehicle’s overall safety and performance standards. In essence, when recycled parts collision repair is executed with such precision, it becomes a sustainable solution without compromising on quality, offering both cost savings and environmental benefits for car bodywork repairs.

The Environmental and Economic Benefits of Using Recycled Parts for Collision Repair

The environmental impact of traditional automotive collision repair is significant, with a high demand for new parts contributing to increased manufacturing processes and resource depletion. However, adopting recycled parts collision repair offers a sustainable alternative. By utilizing recycled components, auto body shops can reduce their carbon footprint and minimize waste generation. This eco-friendly approach aligns with the growing global efforts to promote sustainability in the automotive industry.

Economically, incorporating recycled parts in collision repair is a smart choice. These parts often come at a lower cost compared to new ones, making them an affordable option for both repair shops and customers. Moreover, recycled materials can be just as durable and reliable as new ones, ensuring high-quality car paint services and precise fender repair. This dual benefit of cost savings and quality work makes recycled parts collision repair an attractive and responsible choice in the automotive collision repair sector.

Recycled parts collision repair is not only a sustainable choice but also one that meets or exceeds Original Equipment Manufacturer (OEM) standards. By utilizing recycled components, auto body shops can reduce costs and environmental impact while ensuring the safety and quality of repairs. This innovative approach to collision repair offers a win-win solution for both businesses and the planet, paving the way for a greener future on our roads.