Unveiling Recycled Parts Collision Repair: What to Expect

Recycled parts collision repair offers economic and environmental benefits, reducing waste and provi…….

In the realm of automotive repair, a sustainable and innovative approach is taking the industry by storm—Recycled Parts Collision Repair. This revolutionary process not only offers a cost-effective solution for damaged vehicles but also contributes to environmental conservation by reducing waste and promoting circular economy principles. As the global focus shifts towards sustainability, this article aims to explore every facet of recycled parts collision repair, from its foundational concepts to its profound impact on both the automotive sector and the environment. By delving into various aspects, we will provide a comprehensive understanding of this game-changing practice and its potential for future growth.

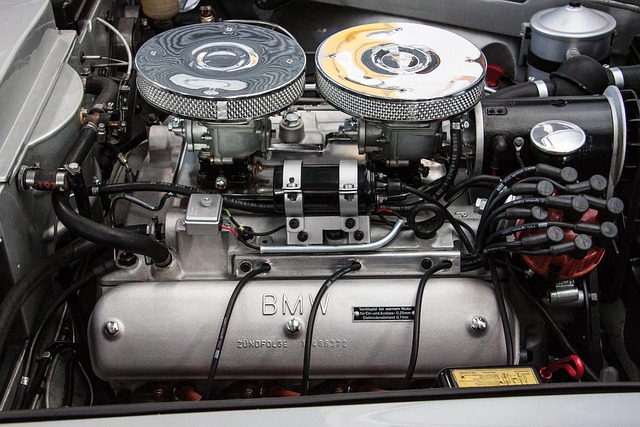

Definition: Recycled Parts Collision Repair is an advanced automotive restoration technique that involves using recycled or reused parts to repair and refurbish damaged vehicles after a collision or accident. This process goes beyond conventional auto body repair by emphasizing the sustainable use of materials, minimizing waste generation, and reducing the demand for new parts production.

Core Components:

Part Selection: The first step is meticulously choosing suitable recycled parts from various sources, including salvage yards, vehicle dismantlers, and remanufactured part suppliers. These parts are assessed for quality, functionality, and structural integrity to ensure they meet repair requirements.

Pre-Treatment and Preparation: Recycled parts often require cleaning, painting, and surface treatment to match the original vehicle specifications. This step ensures aesthetics and long-term durability, making the repaired vehicle nearly indistinguishable from new.

Repair and Refurbishment: Skilled technicians employ advanced techniques to replace damaged components with recycled parts. This includes panel beating, welding, and structural reinforcement, ensuring the vehicle’s safety and performance are restored.

Quality Assurance: Rigorous quality control measures are implemented throughout the repair process. Inspection protocols verify the precision of repairs, part compatibility, and overall vehicle condition before final release to the customer.

Historical Context: The concept of recycled parts collision repair gained traction in response to growing environmental concerns and the increasing availability of high-quality used auto parts. Over time, advancements in technology and a shift towards sustainability within the automotive industry have refined this practice, making it a viable and desirable option for both consumers and businesses.

The influence of recycled parts collision repair extends far beyond national borders, shaping the automotive landscape internationally. Here’s a glimpse into its global impact:

Regional Adoption: Every region has embraced this concept with varying degrees of enthusiasm. North America, Europe, and Asia Pacific have led the way in implementing strict environmental regulations that encourage the use of recycled parts. For instance, the European Union’s End-of-Life Vehicles Directive (ELV) sets ambitious targets for recycling rates, fostering a thriving market for sustainable auto repairs.

Market Growth: The global recycled parts collision repair market is experiencing robust growth, driven by increasing environmental awareness and stricter waste management policies. Market research indicates that the market size was valued at USD 23.4 billion in 2020 and is projected to reach USD 35.7 billion by 2028, growing at a CAGR of 6.1% (Grand View Research).

Regional Variations: While some regions excel in recycling rates, others face challenges due to limited infrastructure and awareness. For example, developing countries might struggle with inconsistent quality standards and the availability of specialized facilities. However, these markets are also witnessing growing interest from automotive manufacturers and consumers who seek sustainable alternatives.

From an economic perspective, recycled parts collision repair presents a unique opportunity to create value while promoting sustainability.

Cost Savings: One of the most significant advantages is the potential for substantial cost savings. Recycled parts are generally more affordable than new or re manufactured components, making this option attractive for both repair shops and vehicle owners. According to a study by the National Automotive Parts Association (NAPA), using recycled parts can reduce repair costs by an average of 25-30%.

Market Dynamics: The market for recycled auto parts operates through a complex network of suppliers, recyclers, repair shops, and consumers. As demand increases, specialized recycling facilities invest in advanced technologies to enhance part recovery rates and improve overall efficiency. This investment can lead to improved economic viability and job creation within the sector.

Economic Impact: The broader implications include reduced strain on natural resources, lower carbon emissions, and potential cost savings for governments through extended vehicle lifespans and reduced waste management expenses. Additionally, this practice fosters local economies by supporting small businesses, such as salvage yards and repair shops, contributing to community development.

Technological breakthroughs have played a pivotal role in transforming recycled parts collision repair into a sophisticated and efficient process.

Advanced Recycling Techniques: Modern recycling facilities employ cutting-edge technologies like robotic sorting systems, advanced metal recovery processes, and computer-aided design (CAD) software for precise part identification. These innovations ensure higher-quality recycled parts, enabling them to meet or exceed the performance of new components.

3D Printing and Additive Manufacturing: 3D printing has emerged as a game-changer in auto body repair. It allows for the reproduction of complex vehicle parts with minimal waste. By combining recycled materials with additive manufacturing, technicians can create custom parts tailored to specific collision damage, enhancing repair precision.

Digital Imaging and Virtual Design: Advanced imaging techniques, such as 3D scanning and laser mapping, enable accurate digital replicas of vehicles before and after repairs. This technology facilitates remote consultations, part sourcing, and quality assurance, streamlining the entire repair process.

Governments worldwide play a crucial role in promoting recycled parts collision repair through regulatory frameworks and policy interventions.

Environmental Regulations: Many countries have implemented strict environmental policies to reduce automotive waste. These regulations mandate specific recycling rates, encourage the use of recycled materials, and penalize non-compliance. For instance, the EU’s ELV Directive sets a target of 90% vehicle weight for recycling and 85% for reutilisation by 2030 (European Commission).

Incentives and Subsidies: Some governments offer financial incentives to businesses and consumers who opt for recycled parts. Tax breaks, rebates, and subsidies can significantly encourage the adoption of sustainable practices within the automotive repair sector.

Standardization and Certification: To ensure quality and consistency, various organizations have developed standards and certification programs for recycled auto parts. These include global initiatives like ISO 16504 (Automotive Recycling) and regional programs specific to North America and Europe. Certification ensures that recycled parts meet specific performance, safety, and environmental criteria.

Despite its numerous benefits, recycled parts collision repair faces certain challenges and criticisms that require thoughtful solutions.

Quality Concerns: One of the primary criticisms revolves around quality standards. Skeptics argue that recycled parts may not match the performance and durability of new components. However, rigorous testing and certification processes can address these concerns. Independent studies comparing recycled and new parts have shown minimal performance differences (Automotive Aftermarket Association).

Limited Infrastructure: Insufficient recycling infrastructure in some regions hinders widespread adoption. To counter this, governments and private sectors should invest in establishing specialized facilities and promoting industry collaboration. Public-private partnerships can drive innovation and create sustainable supply chains for recycled parts.

Consumer Awareness: Many consumers remain unaware of the benefits of recycled parts collision repair. Educating the public about environmental advantages, cost savings, and the quality of recycled parts is essential. Marketing campaigns, collaborations with automotive manufacturers, and in-shop displays can help dispel myths and encourage informed choices.

Exploring successful applications of recycled parts collision repair provides valuable insights into its practical implementation.

Case Study 1: Green Auto Repair, USA

Green Auto Repair, a renowned boutique collision center in California, has made sustainability its cornerstone. They specialize in using eco-friendly practices and recycled parts for all their repairs. By partnering with local recyclers and investing in state-of-the-art sorting technology, they ensure high-quality recycled components. Green Auto Repair has achieved remarkable success, reducing waste by 85% and saving an average of 20% on repair costs while maintaining exceptional vehicle aesthetics.

Case Study 2: Eco-Friendly Motors, UK

Eco-Friendly Motors, a leading automotive restoration company in the UK, has pioneered recycled parts collision repair in Europe. They offer comprehensive repairs using only certified recycled and remanufactured parts. By adopting advanced CAD design and 3D printing technologies, they can create precise custom parts. This approach has resulted in significant environmental benefits, including a 70% reduction in vehicle waste sent to landfills and a 15% decrease in carbon emissions compared to traditional repair methods.

Case Study 3: Asia Pacific Auto Refurbishers (APAR), Japan

APAR, a Japanese conglomerate specializing in automotive refurbishment, has established itself as a global leader in recycled parts collision repair. They have developed an innovative system that collects and recycles vehicle components from end-of-life vehicles, utilizing advanced sorting and processing technologies. APAR’s commitment to sustainability has led to the development of high-quality recycled parts, reducing the environmental footprint of the automotive industry in Asia Pacific.

The future of recycled parts collision repair looks promising, with several emerging trends shaping its trajectory.

Increased Adoption by Manufacturers: Major automotive manufacturers are recognizing the benefits of sustainable practices and integrating them into their supply chains. Many are investing in recycling technologies and partnering with specialized facilities to ensure a steady supply of high-quality recycled parts. This collaboration will drive innovation and improve the overall market landscape.

Digitalization and Remote Services: The integration of digital technologies, such as remote consulting and online part sourcing, is expected to grow. Advanced imaging and virtual design tools enable technicians to provide expert advice remotely, expanding access to specialized knowledge.

Circular Economy Expansion: As the concept of a circular economy gains traction, recycled parts collision repair will play a pivotal role in closing the loop for automotive waste. Future developments may include closed-loop recycling systems, where components are reused and redistributed within a controlled supply chain.

Sustainable Materials Research: Ongoing research into sustainable materials, including bio-based composites and advanced recycling methods, will drive further innovation. These breakthroughs could lead to even more eco-friendly alternatives, expanding the scope of recycled parts collision repair.

Recycled parts collision repair represents a significant step towards a more sustainable and resilient automotive industry. Its global impact, economic benefits, technological advancements, and policy support underscore its importance as a game-changer in the way we restore and reuse vehicles. By addressing challenges through innovative solutions and learning from successful case studies, this practice is poised to revolutionize automotive restoration worldwide.

Q: Are recycled parts safe for my vehicle?

A: Recycled parts undergo rigorous testing and quality control measures to ensure they meet or exceed safety standards. Certified recycled parts are designed to perform just like new components, providing safe and reliable vehicle operation.

Q: How do I know if a repair shop uses recycled parts?

A: Many reputable repair shops proudly display certifications and eco-labels on their facilities or websites. Ask your mechanic about their part sourcing practices and look for professional associations or industry awards that promote sustainable repair methods.

Q: Are there any cost advantages to using recycled parts?

A: Absolutely! Recycled parts can offer significant cost savings, with some studies indicating up to 30% reduction in repair expenses. This makes them an attractive option for consumers and businesses looking to optimize their automotive restoration budgets.

Q: Can recycled parts be used for all types of vehicle repairs?

A: While recycled parts are versatile, their suitability depends on the specific damage or required replacement. For complex structural repairs or rare vehicle models, new or specialized remanufactured parts might be necessary. However, for routine damages, recycled parts offer a viable and sustainable alternative.

Q: How does recycled part collision repair contribute to environmental conservation?

A: This practice significantly reduces automotive waste by extending the lifespan of vehicles and their components. By minimizing landfill waste and lowering manufacturing costs (due to recycled material use), it decreases carbon emissions and conserves natural resources, contributing to a greener planet.

Recycled parts collision repair offers economic and environmental benefits, reducing waste and provi…….

Choosing a shop specializing in recycled parts collision repair is an environmentally responsible an…….

Recycled parts collision repair is a growing trend in the automotive industry, aiming for sustainabi…….

Recycled parts collision repair offers significant cost savings due to lower demand and manufacturin…….

The adoption of recycled parts collision repair offers significant environmental and economic benefi…….

Recycled parts collision repair offers a sustainable, cost-effective solution for auto repairs, redu…….

Recycled parts collision repair offers significant cost savings and environmental benefits by meticu…….