Recycled parts collision repair prioritizes cost efficiency and environmental stewardship by using salvaged components from damaged vehicles. Reputable recyclers employ rigorous grading and testing to ensure parts meet high performance standards, offering budget-friendly, quality solutions for car restoration and repairs while preserving resources. Stringent quality assurance includes inspections, advanced testing, and documentation, providing customers with peace of mind and promoting a sustainable automotive industry.

In the realm of automotive collision repair, utilizing recycled parts offers both environmental and economic benefits. However, ensuring quality is paramount to prevent compromising safety and vehicle performance. This article guides you through the process of verifying quality in recycled parts collision repair. We’ll explore essential aspects such as understanding recycled parts, setting stringent quality assurance standards, and implementing rigorous testing and certification procedures to ensure reliability and customer satisfaction in this eco-friendly approach.

- Understanding Recycled Parts in Collision Repair

- Setting Standards for Quality Assurance

- Testing and Certification Procedures for Recycled Auto Parts

Understanding Recycled Parts in Collision Repair

Recycled parts have become an integral part of the collision repair industry, offering both cost-effectiveness and environmental sustainability. In the context of recycled parts collision repair, these parts are typically salvaged from damaged or end-of-life vehicles, processed, and then used to replace like components on other cars. This process not only reduces waste but also makes high-quality, often barely used parts accessible at a lower cost.

Understanding the nuances of recycled parts is crucial in ensuring their quality during car collision repair or hail damage repair. Reputable recyclers employ meticulous processes to grade and inspect these parts, guaranteeing they meet specific performance standards. Incorporating recycled parts into car restoration efforts allows for both budget-conscious repairs and the preservation of resources, making them a viable and responsible choice for many automotive professionals and vehicle owners alike.

Setting Standards for Quality Assurance

In the realm of recycled parts collision repair, establishing robust quality assurance standards is non-negotiable. This involves setting clear guidelines and specifications for every stage of the repair process, from material sourcing to final inspection. By implementing rigorous protocols, workshops can ensure that recycled components meet or exceed industry standards in terms of strength, durability, and aesthetics. Standardized quality checks, including thorough inspections and advanced testing methods, are essential tools to verify the integrity of these parts, especially when it comes to hidden flaws or structural weaknesses often associated with hail damage repair.

Moreover, focusing on precision during the remanufacturing process is key. Skilled technicians play a pivotal role in ensuring that recycled parts are not just functional but also possess excellent cosmetic qualities. This attention to detail extends to car paint services, where paintless dent repair techniques can restore vehicles to their original state, minimizing the need for extensive repainting. Through consistent adherence to these standards, recycled parts collision repair shops can offer high-quality, cost-effective solutions while contributing to a more sustainable automotive industry.

Testing and Certification Procedures for Recycled Auto Parts

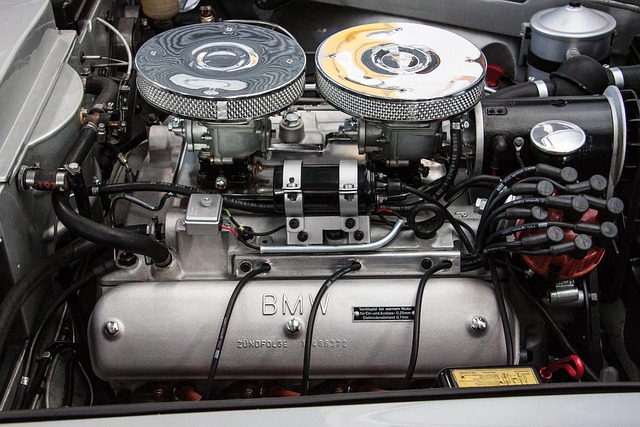

In the realm of recycled parts collision repair, ensuring quality is paramount to guarantee safe and reliable vehicle repair. Testing and certification procedures play a crucial role in verifying the integrity and performance of these used auto parts. Reputable recycling facilities employ rigorous testing methods to assess the condition and functionality of components, such as fenders, doors, and hoods, before they enter the market. These tests often involve visual inspections, material analysis, and structural strength evaluations to detect any signs of damage or wear resulting from previous accidents or hail damage repair attempts.

Certification bodies independently validate these testing procedures, ensuring compliance with industry standards. This process involves thorough documentation and tracking of each part’s history, including its source and any repair or replacement work done. By adopting these stringent measures, recycled parts collision repair providers offer customers peace of mind, assuring them that the used components are not only environmentally friendly but also meet the same quality standards as new parts, thereby facilitating efficient and cost-effective vehicle repair without compromising safety in cases of minor fender benders or extensive hail damage repairs.

When it comes to recycled parts collision repair, ensuring quality is paramount. By setting clear standards, implementing rigorous testing procedures, and seeking certified components, repair shops can deliver reliable, cost-effective, and eco-friendly solutions. Understanding the value of these processes allows for a seamless transition to a more sustainable auto repair landscape, ultimately benefiting both businesses and consumers alike in the long run.